Procedure

S-Flex Coupling Variety Method

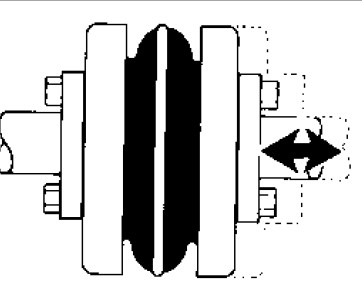

The selection course of action for identifying the proper S-Flex coupling involves applying the charts shown on the following pages. You will discover 3 elements to become picked, two flanges and one sleeve.

Details vital prior to a coupling is usually chosen:

HP and RPM of Driver or working torque

Shaft size of Driver and Driven tools and corresponding keyways

Application or products description

Environmental ailments (i.e. extreme temperature, corrosive disorders, space limitations)

Ways In Selecting An S-Flex Coupling

Step 1: Decide the Nominal Torque in in-lb of the application by using the following formula:

Nominal Torque = (HP x 63025)/RPM

Step 2: Making use of the Application Support Issue Chart 1 choose the support factor which greatest corresponds for your application.

Stage 3: Determine the Style and design Torque of the application by multiplying the Nominal Torque calculated in Step one through the Application Service Aspect established in Phase 2.

Style and design Torque = Nominal Torque x Application Support Component

Step four: Making use of the Sleeve Efficiency Data Chart two select the sleeve material which most effective corresponds to your application.

Stage 5: Using the S-Flex Nominal Rated Torque Chart three find the suitable sleeve material column to the sleeve selected in Stage 4.

Phase 6: Scan down this column towards the first entry wherever the Torque Worth within the column is greater than or equal for the Style Torque calculated in Stage three.

Refer for the greatest RPM value of the coupling dimension to make certain the application specifications are met. If your optimum RPM worth is less than the application necessity, S-Flex couplings are usually not encouraged for your application.

Note:

If Nominal Torque is less than 1/4 from the coupling’s nominalrated torque, misalignment capacities are reduced by 1/2. As soon as torque value is found, refer to the corresponding coupling dimension in the to start with column from the S-Flex Nominal Rated Torque Data Chart 3 .

Step seven: Compare the application driver/driven shaft sizes on the optimum bore size accessible about the coupling chosen. If coupling max bore isn’t huge adequate for your shaft  diameter, choose the next greatest coupling that can accommodate the driver/driven shaft diameters.

diameter, choose the next greatest coupling that can accommodate the driver/driven shaft diameters.

Phase 8: Utilizing the Item Assortment tables, discover the appropriate Keyway and Bore size essential and locate the quantity.