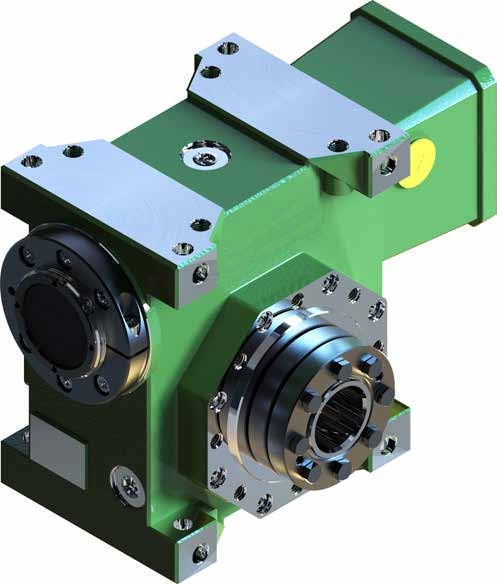

JDLB Capabilities

Servo worm gear units have 6 types :45 – 50 – 55 – 63 – 75 – 90, with dual lead worm drive. Left and suitable flank of worm shaft using distinct lead angle leading to tooth thickness gradual change. So that you’ll be able to move worm shaft

and change backlash.

JDLB Applications

Precision rotary motion

— Cutting down the noise and vibration which is induced by the load adjust as well as

transform of cutting force.

— decreasing the noise and affect that’s caused by the corotation and reverse.

— By decreasing worm abrasion.

— Growing worm output response pace.

Precision Indexing gadget

— CNC machine, assembly line, cutting machine, transmission lines, etc.

— Indexing device, correct studying mechanism call for exact movement

occasions.

Speed changing conditions.

— Minimizing the noise as well as the impact that may be caused by velocity change.

— Minimizing the worm abrasion that may be caused by pace improvements.

JDLB Make preference

The following headings consist of information on critical components for

assortment and appropriate use of gearbox.

For specific information around the gearbox range, see the appropriate chapters.

EFFICIENCY

Efficiency is really a parameter which features a major influence on the sizing of selected applications, and in essence is determined by gear pair design and style factors.

The mesh data table on web page 9 exhibits dynamic efficiency (n1=1400)and static efficiency values.

Bear in mind these values are only achieved following the unit has been run in and is with the operating  temperature.

temperature.